Features of mini concrete batching plant

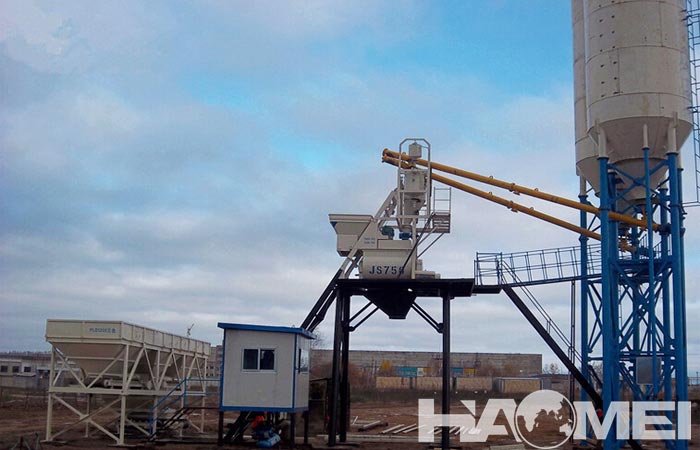

The mini concrete batching plant stands for concrete batching plant with lower capacity and cost. Is is also can be called as small concrete batching plant. The mini concrete batching plant uses lifting hopper to feeding, in other words, it is skip type concrete batching plant. The mini batching plant takes a small amount of space, which can save up to one-half to two-thirds of the area of land occupied by a conventional inclined-belt conveyor type concrete batching plant.

The main body of the stirring system can be fixed on the steel beam or stationary type, steel beam type concrete mixing plant can be removed from the transport vehicle and installed for only a few hours, together with the installation of other equipment such as control rooms and batching stations. The installation of the mini stationary concrete batching plant can be completed in only two to four days. What’s more, the cost of mini concrete batching plant is much lower than commercial concrete batching plants, so when applied in small projects, the mini type is favored. The most used model of the mini concrete plant is HZS25 concrete batching plant which has the mixing capacity of 25 m3/h. Although the capacity id small, but the performance of the mini batching plant is still very good, which can fully meet the requirement of concrete production, this is also another method to save cost.