Twin Shaft Concrete Mixer Working Principle

As a core model among concrete mixing equipment, the twin shaft concrete mixer is widely used in commercial concrete batching plants, precast component factories, and large-scale infrastructure construction sites due to its high-efficiency mixing performance and uniform material mixing effect. Its core working principle lies in the forced mixing trajectory formed by the coordinated operation of the two shafts, breaking up material agglomeration and achieving precise and homogeneous mixing of aggregates, cement, admixtures, and water. Compared to single-shaft concrete mixer models, the design logic of the twin-shaft structure focuses more on solving industry pain points such as poor homogeneity and long mixing time in the mixing process of high-grade concrete and special concrete.

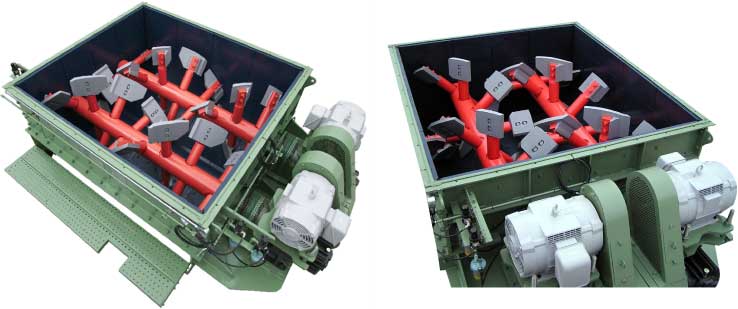

1. Power transmission and motion conversion mechanism

From the perspective of power transmission and motion conversion, the operation of the twin shaft concrete mixer begins with the coordinated action of the power system and the transmission mechanism. Typically, a heavy-duty geared motor paired with a hardened gearbox is used for drive. The high-speed rotational motion output by the motor is converted into low-speed, high-torque rotation of the two shafts after passing through the reduction mechanism. The speed is generally controlled within the optimal range of 28-32 r/min—this speed parameter is a balanced value derived from extensive testing, ensuring that the material is fully thrown up and tumbled while avoiding material splashing and energy loss due to excessive speed. It is worth noting that the rotation directions of the two shafts are relatively opposite. This design is not a simple symmetrical layout, but rather a precise transmission through gear meshing that keeps the linear velocities of the two mixing shafts consistent, providing a foundation for the subsequent mixing trajectory formation.

2. Core mixing process and force system analysis

The mixing process after the material enters the mixing drum is the core manifestation of the working principle of a twin shaft concrete mixer. The mixing blades arranged on the mixing shafts at specific helical angles and spacing exert forces on the material in two directions when rotating in opposite directions: one is an axial force that reciprocates along the axial direction, and the other is a shearing and tumbling force perpendicular to the axial direction. Under axial force, the material reciprocates along the length of the mixing drum, preventing localized material accumulation. Simultaneously, the counter-rotating blades create a cross-mixing trajectory, breaking down and dispersing large aggregate particles, ensuring the cement paste fully coats the aggregate surface. For special concretes such as self-compacting concrete and fiber-reinforced concrete, the biaxial structure can further address fiber agglomeration and paste separation by optimizing the blade layout (e.g., using composite blades with side mixing arms). The mixing homogeneity error can be controlled within 3%, far superior to the 8% error standard of single-shaft models.

3. Dynamic balance and energy optimization during mixing

During mixing, the dynamic balance of the material and energy transfer are equally crucial. The biaxial mixing system, through a well-designed drum wall liner (typically high-chromium wear-resistant liner with a thickness ≥12mm), works in conjunction with the mixing blades to reduce frictional loss between the material and the drum wall. Simultaneously, it guides the material to form a stable figure-eight mixing trajectory—this trajectory ensures a more uniform residence time of the material within the mixing drum, reducing the average mixing time to 45-60 seconds, resulting in an efficiency improvement of over 30% compared to single-shaft models. Furthermore, the twin shaft structure provides more balanced stress distribution, with both shafts sharing the mixing load. This extends the shaft system's service life by 50% compared to single-shaft models, significantly improving equipment stability. It is particularly suitable for large-scale, continuous mixing plants, where daily mixing capacity can exceed 2000 m³.

4. Discharge stage and closed-loop control guarantee

The discharge stage is the final stage of the working principle, again showcasing the advantages of the twin shaft structure. Once the material reaches the set homogeneity, the discharge gate at the bottom of the mixing drum opens, and the dual shafts continue operating. The axial pushing force of the blades is then converted into discharge power, rapidly pushing the uniformly mixed concrete to the discharge port. Due to the coordinated pushing of the dual shafts, the discharge process is residue-free and blockage-free, increasing the discharge speed by 40% compared to single-shaft models, effectively avoiding initial setting problems caused by untimely discharge. It is important to emphasize that throughout the entire operation, the control system of the twin shaft concrete mixer monitors parameters such as shaft load and mixing time in real time. When the load exceeds the set threshold (usually 120% of the rated load), the system will automatically adjust the speed or issue an early warning to ensure the safe operation of the equipment. This closed-loop control logic also provides a guarantee for the efficient implementation of the working principle.